Two of the largest sub-Saharan solar systems have been unveiled in Johannesburg.

The Soltrain (Southern African Solar Thermal Training and Demonstration Initiative) projects, a district heating plant for Wits University residences and a solar process heat plant for the Klein Karoo International (KKI) tannery, will save millions in energy costs over the lifetime of the plants.

They were unveiled by the Austrian ambassador.

Soltrain in South Africa is managed by the Centre for Renewable and Sustainable Energy Studies at Stellenbosch University, and the South African National Energy Development Institute (SANEDI), in partnership with AEE-Institute for Sustainable Technologies (AEE INTEC) from Austria.

Soltrain is a regional initiative on capacity building and demonstration of solar thermal systems in the SADC region. It is funded by the Austrian Development Agency and co-funded by the OPEC Fund for International Development.

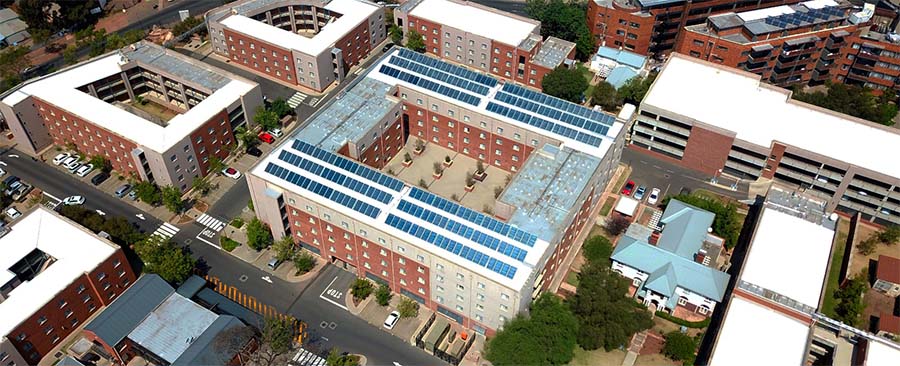

Wits Junction

The Wits Junction district heating project combines solar, co-generation and gas heating technologies, servicing 14 student residence buildings with hot water from one centralised hot water plant room. The installation includes 600m2 solar heating plant with 10m2 Austrian collectors.

There are 1 103 students in the 14 buildings, with an average consumption of 94 000 litres of hot water per day. Peak demand is in the morning, averaging 30% of daily consumption, with a maximum demand of 28 200 litres in an hour.

The system supplies the entire hot water demand, including kitchens, laundry, cleaning and other domestic uses. Each student has his/her own kitchen and there are some centralised service rooms for cleaning staff.

Since the system was commissioned, the complaints of not having hot water have reduced by 98%. The estimated costs savings are R40-million over the next 20 years and already the university has seen substantial electricity savings over the trial period of eight months.

As the electricity cost from the co-generator is equal to municipal cost, the thermal energy is free and the centralised plant requires a lot less maintenance intervention, hence less costs.

Klein Karoo tannery

The KKI tannery section has installed a 600 m2 solar collector system to reduce costs and increase competitiveness, since fuel costs are highly volatile, and to move its production to a more renewable base.

Stellenbosch University approached various tanneries for process heat application viabilities and this tannery was the most forthcoming and had the budget to contribute to the study. The process heat infrastructure is an oil burner and the feasibility study design was that the solar would displace the local fuel, indicated as 60% solar fraction.

Stellenbosch University predicted a payback of 6,5 years, based on a financial model analysis from the feasibility study, which includes maintenance, finance costs and all system related expenses.

Dr Karen Surridge, centre manager: Renewable Energy Centre of Research and Development at SANEDI, comments “SANEDI is delighted to be associated with such landmark developments that put the Soltrain projects firmly on the renewables table. The successful conference we have just held with Soltrain partners indicates the relevance of this highly successful programme for the SADC renewable energy strategy and the development in successful systems across six countries.”

A drone-eye view of the Wits Junction installation.