Events of the past year have upended the procurement industry, illustrating the fragility of a complex international supply chain and forcing a sea change in the industry.

However, according to the 2021 Supply Chain Insights Global Survey from IHS Markit, supply chain professionals often lack the tools, data and platforms needed to diversify their supply chains and optimise their processes.

“Supply chains can no longer operate as siloed, disconnected functions; recent events such as the Covid-19 pandemic and the Suez Canal saga, have illustrated the need for supply chains to be resilient and agile,” says Wilhelm Greyling, executive director: supply chain solutions at IHS Markit.

“Supply chains can only truly be optimised via end-to-end collaboration and visibility. As the old saying goes, you can’t manage what you can’t see; an integrated approach is not only a nice to have, its essential.”

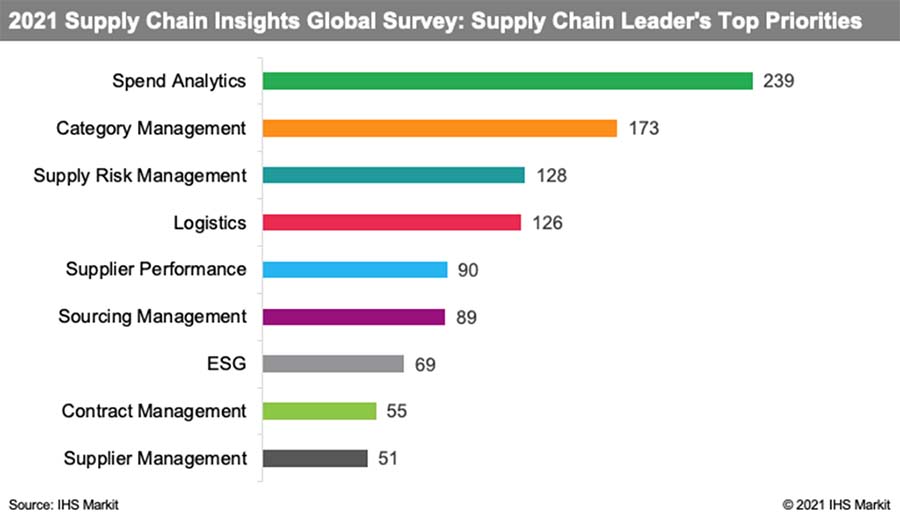

Conducted earlier this year, the 2021 Supply Chain Insights Global Survey asked respondents to identify their priorities and capabilities in three key industry capabilities: strategy and process, platforms and technology and intelligence, insight and expertise across nine functional elements. Responses were compiled from 340 supply chain leaders across 60 countries and 33 industries.

While respondents noted prioritising spend analytics and reported having a strategy in place to optimise costs, 63% lacked the necessary data, platforms and technology needed to make critical cost-saving decisions.

The results represent a clear misalignment between strategic intent and capability and send a signal that significant investment is needed in technology, platforms and data to enable and deliver overall supply chain objectives.

Surprisingly, supplier risk management and ESG were prioritised as among the least important considerations, at nine and seven, respectively. Only 51% of supply chain leaders surveyed reporting having a strategy in place to combat ESG issues.

“Increasing legislation and regulation will continue to drive the importance of third-party risk management and ESG considerations, as companies increasingly become accountable not only for their own actions, but also for that of their suppliers,” says Greyling.

“The reluctance in investment into the areas of third-party risk and ESG could easily wipe out a firm’s cost-optimization gains, as the penalties for oversights or breaches can be severe.”

The survey results signaled that, in today’s world of complex supply chains, one missing link can have drastic cost and reputational benefits. Successful supply chains of the future will need to balance precise cost optimisation strategies with a proactive approach to risk management and ESG considerations.